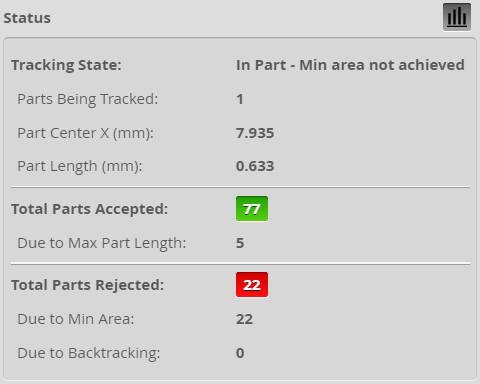

Part Detection Status

One of the most common issues when setting up part detection is that surface data is not generated after the target is scanned. The Status section on the Part Detection panel allows you to see details on the status of the part detection engine. This can be used to diagnose why parts are not being detected during setup, reducing setup time.

The following part detection status information is available:

| Status Indicator | Description |

|---|---|

|

Tracking State |

Part detection state for largest currently tracking part. One of the following:

|

|

Parts Being Tracked |

The number of parts the engine is currently tracking. |

|

Part Center X |

The center of the partial part, midway between the minimum X and maximum X detected for the part. |

|

Part Length |

The length of the part. In cases of backtracking, the number decreases. |

|

Total Parts Accepted |

The number of parts that meet the part detection criteria. |

|

Due to Max Part Length |

The number of parts accepted because they have reached Max Part Length. If too many parts are being accepted, increase Max Part Length. |

|

Total Parts Rejected |

The number of parts that fail to meet the part detection criteria. |

|

Due to Min Area |

The number of parts rejected because they are below Min Area. If too many parts are being rejected, reduce Min Area. |

|

Due to Backtracking |

The number of parts rejected due to backtracking, for example, when the user reverses the direction of the transport mechanism while the sensor is actively scanning a part. Only applicable when the encoder trigger behavior has been set to Bi-Directional. |