Ring Layouts (Surface Align Ring Tool)

|

This tool requires acceleration (either by a PC-based application or by GoMax). |

|

The tools described in the following sections are only intended to be used with G2 sensors. |

|

LMI strongly recommends disabling Uniform Spacing on the Scan page for the alignment procedure, as this will simplify the configuration of the alignment tools. (For more information on configuring uniform spacing, see Scan Modes.) After you have completed the alignment procedure, you can enable Uniform Spacing if your application requires it: the setting does not have to match between the alignment procedure and in jobs you use in production. |

You can use the Surface Align Ring tool to align a multi-sensor system in a ring layout or a dual- or multi-sensor partial ring layout with 6 degrees of freedom. The alignment procedure saves the transformations required for the sensors in an XML file. Unlike alignment performed using the Alignment panel, the tool also compensates for X angle rotation (giving you a full six degrees of freedom).

Note that in order to perform scans in production, you must use the Surface Mesh tool (loading the transform XML file created by this tool) to stitch the scans from the individual sensors into Mesh data; for more information on the Surface Mesh tool, see Mesh. You can then either perform measurements directly on the Mesh data using the Mesh measurement tools (see Mesh Measurement) or you can extract Surface data from the Mesh data and apply any built-in or custom GDK-based Surface tools to the resulting data (see Surface Measurement).

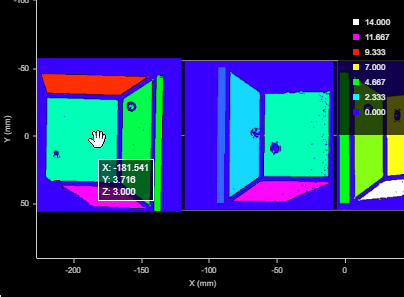

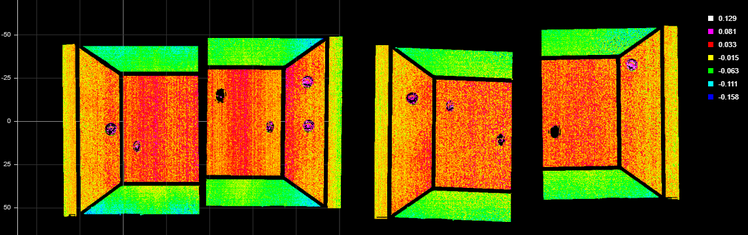

Difference Surface data output resulting from an alignment (available on the Data tab, used for diagnostics).

|

If you have configured the layout so that some sensors are located in the bottom row of the layout grid, make sure to select Top & Bottom in Source when using this tool. For more information on layouts, see Layout. |

Alignment Target

This alignment tool requires the use of a double-sided truncated pyramid alignment target. You can find CAD files for this type of target under Tools\Alignment CAD\Double Sided Pyramid in the Utilities package (e.g., 14405-x.x.xx.xx_SOFTWARE_GO_Utilities.zip, available on LMI's Product Downloads page). Note that you should adapt the size of the alignment target to the size of the sensors in your system: the target should be scaled so it fills most of the field of view of a sensor.

Example dimensions for mid-size FOV sensors.

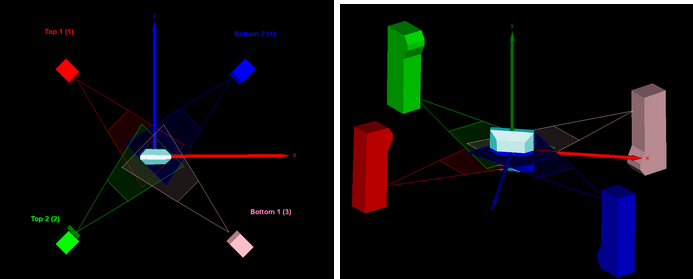

The following is a simulated representation of a four-sensor setup around an alignment target:

Note that after using this tool, on the Alignment panel on the Scan page, Gocator indicates that the sensor is unaligned.

The following requirements should be satisfied for best results:

-

Make sure the alignment target surface is not too shiny or too dark to be scanned.

-

Maximize the size: The target should fill the scan volume of each sensor but not extend past the field of view of the sensors.

-

Edges do not need to be perfectly sharp: The alignment tool performs a plane fit to points within the planar surfaces and excludes data close to the edges.

-

No planar surfaces other than those on the alignment target should be visible in the scan results. For example, do not scan the target set on a flat surface such that the surface is included in the scan results.

-

Each sensor in the system must be able to properly scan a minimum of 5 planar surfaces of the alignment target. If necessary, rotate the alignment target to ensure this.

-

Ensure the ratio of X and Y scan resolution does not exceed 5. For more information on setting X resolution, see Spacing. For information on setting Y resolution, see Trigger Settings.

Procedure Overview

The following provides an overview of the steps involved in performing a high-accuracy, tool-based alignment.

To perform the alignment:

| 1. | Set up and configure the multi-sensor system. |

The following sections describe setting up and configuring a system:

| 2. | Fabricate an alignment target appropriate for your system (wide or side-by-side layout versus ring layout). |

For details on the alignment target, see Alignment Target.

|

Although you can scan the alignment target without acceleration, you must perform the alignment using PC-based acceleration (for more information, see Software-Based Acceleration). Because starting acceleration after having performed a scan clears scan data from a sensor, if you are going to perform alignment on-sensor, you should start acceleration before continuing. You can also optionally download the sensor state and scan data as an emulator scenario and perform the alignment on the scanned target using the emulator. For more information, see Downloading a Support File and Running the Emulator. |

|

Make sure you have decided whether to enable or disable Uniform Spacing on the Scan page before proceeding. For important information, see Using Uniform Spacing During the Alignment. |

| 3. | Enable recording by clicking the Record button. |

| 4. | Start the transport system and then perform a scan of the alignment target. |

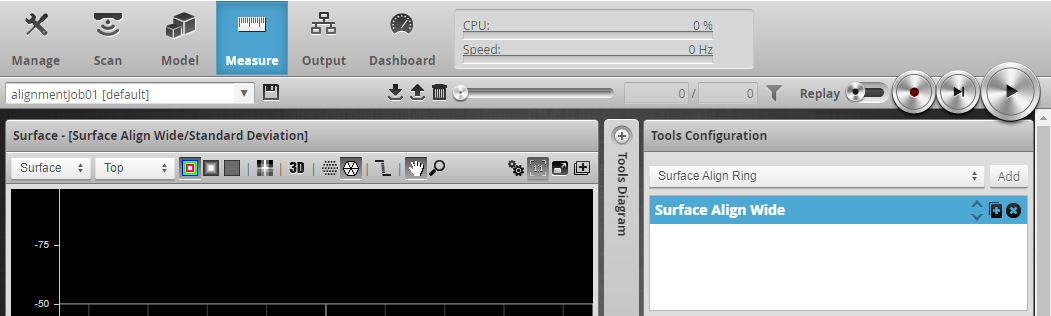

| 5. | On the Measure page, add a Surface Align Ring tool. |

| 6. | If you have a "Start" initialization file (see above), choose Load from the Operation drop-down, load that file, and go to step 12. |

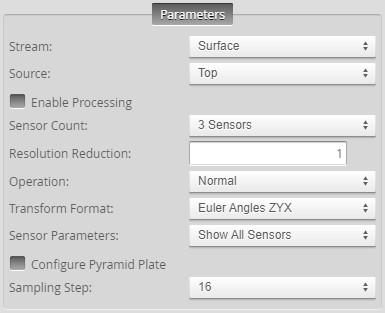

| 7. | Set Sensor Count to the number of sensors in the system. |

| 8. | Under Sensor Parameters, select the sensors, one by one, and configure the parameters related to the sensor's position. |

For more information, see Sensor Parameters.

| 9. | Check Configure Pyramid Plate and configure the parameters related to the alignment target. |

For more information, see Double-Sided Pyramid Configuration Parameters.

| 10. | Configure the alignment tool's remaining parameters and enable the diagnostics data outputs (on the tool's Data tab) if needed. |

| 11. | Check the Enable Processing checkbox. |

The tool processes the scan data, using the provided sensor transformations and alignment target configuration, and saves an XML transformation file to C:/GoTools/SurfaceAlign. If the alignment process succeeds, the Calibration Status field displays the time and date of the alignment.

You must the load the resulting XML file in a Surface Mesh tool, typically in a separate job, which transforms the multi-sensor scan data into a common coordinate system and produces a Mesh output. You can then apply other measurement tools to the merged scan data. For more information on the merging tool, see Mesh.

Measurements, Data, and Parameters

| Measurement |

|---|

|

Uncertainty Alignment uncertainty (an indicator of alignment quality). |

|

Origin X{n} Origin Y{n} Origin Z{n} The X, Y, and Z transformations calculated for sensor {n}. |

|

Rotation X{n} Rotation Y{n} Rotation Z{n} The X, Y, and Z angle transformations calculated for sensor {n}. |

|

Processing Time The time the tool takes to run. |

|

Enable Processing must be checked to view the following diagnostic data outputs. |

| Parameter | Description |

|---|---|

|

Source |

The sensor |

|

Enable Processing |

Starts the alignment procedure. Make sure to properly configure the tool before enabling this option. Disable it after performing the alignment; otherwise, the tool will continue performing the alignment on new frames of data, which will have an impact on performance. (Ideally, you should use a separate job for the alignment procedure.) |

|

Operation |

Actions that apply to the tool's XML initialization files. One of the following:

|

|

Sensor Count |

Indicates the number of sensors in the system. |

|

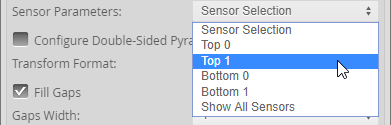

Sensor Parameters |

A drop-down that display the settings of the selected sensor. For descriptions of the individual sensor parameters used for the alignment, see Sensor Parameters. |

|

Configure Double-Sided Pyramid |

If enabled, displays parameters that let you configure the pyramid plate's specifications. For descriptions of the pyramid plate parameters, see Double-Sided Pyramid Configuration Parameters. |

|

Transform Format |

The transformation format the tool uses. Choosing a different format may be useful if you need to compare what the sensors detect to the transformation format used in your CAD package, for example. The setting does not affect alignment. One of the following:

|

|

Fill Gaps |

When this option is enabled, the tool displays a Gaps Width parameter (see below). |

|

Gaps Width |

The kernel the tool uses to initially calculate the surface normal required for alignment. Typically, a value of 4 works for most applications. If alignment fails and you can't track down the issue, try a different value. |

|

Sampling Step |

The step in data points in both directions with which the surface is sampled. Choosing a higher sampling step reduces the processing time the tool requires, but reduces fit accuracy. Typically, you will want to use as low a sampling step as possible; use a high sampling step only for initial testing purposes. |

|

Resolution Reduction |

Reduces the lateral resolution of the heightmap to reduce processing time. |

|

Filters |

The filters that are applied to measurement values before they are output. For more information, see Filters. Not typically used with this tool. |

|

Decision |

The Max and Min settings define the range that determines whether the measurement tool sends a pass or fail decision to the output. For more information, see Decisions. Not typically used with this tool. |

| Parameter | Description |

|---|---|

|

Invert Y Direction

|

Converts from a left-handed coordinate system to a right-handed coordinate system. Enable this only if the sensor is mounted in a reverse position and identified as Reverse in Layout on the Manage page. (That is, the transport system moves in the same direction as the sensor's positive Y direction. For more information, see the description of the sensor's Y axis in the model's Coordinate System Orientation in the sensor's specification drawings.) |

|

Sensor Model

|

Sets the sensor's model. |

|

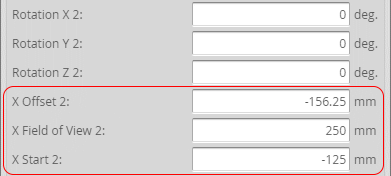

Rotation X {n} Rotation Y {n} Rotation Z {n} |

The X, Y, and Z rotations for sensor {n}. In order for the alignment to succeed, you must enter the rough orientation of the sensors. |

|

X Offset {n} X Field of View {n} X Start {n} |

These parameters are only displayed if Uniform Spacing is enabled. LMI strongly recommends disabling uniform spacing when performing an alignment with Surface Align Ring. For more information, see Using Uniform Spacing During the Alignment. |

The following image indicates which parameters correspond to which parts of the alignment target. For the parameters, see the table below.

Using Uniform Spacing During the Alignment

If you choose to enable Uniform Spacing during the alignment, you must perform these additional steps. Otherwise, the alignment will fail.

These steps separate the individual sensors' scan data in the heightmap so that the alignment tool can process the scan data from each sensor individually. To do this, you set artificial offsets along the X axis to separate the scan data so that there is no overlap between the sensors.

Do the following:

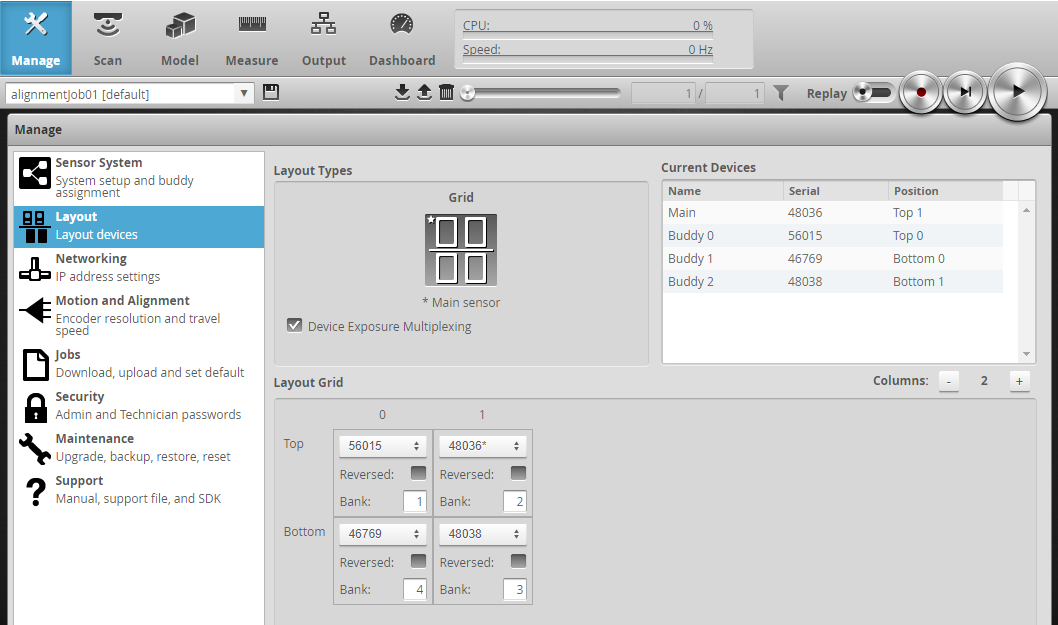

| 1. | (Optional) In the web interface, go to the Manage page, click the Layout section, and make note of the names, serial numbers, and positions listed in the Current Devices table. |

This information will be useful when you continue configuring the system in other parts of the web interface.

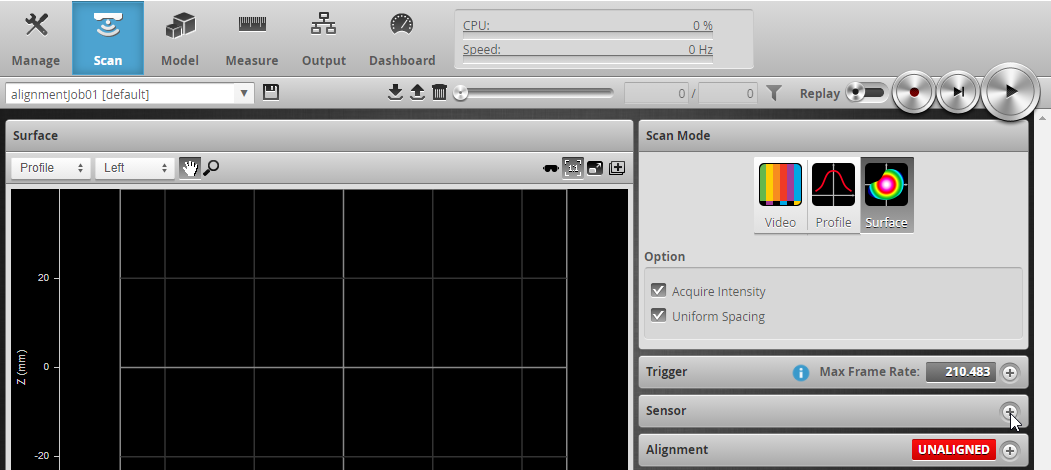

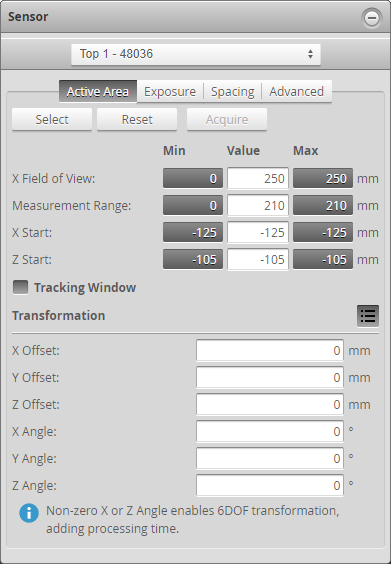

| 2. | In the web interface, go to the Scan page, expand the Sensor panel, and in that panel, expand the Transformation area. |

| 3. | For each sensor in the system, in the Active Area tab, make note of the values for X Field of View and X Start. |

| 4. | For each sensor in the system, in the Transformation area, set X Offset to a value that eliminates any overlap between sensors, and make note of this value. |

For systems with more than two sensors, simply set the offsets to ensure that the individual sensors' scan data in the heightmap does not overlap.

| 5. | Go to the Measure page and add an instance of Surface Align Ring. |

| 6. | For each sensor, select the sensor you need to configure in the Sensor Parameters drop-down and copy the "X Field of View," "X Start," and "X Offset" values from the Scan page into the corresponding parameters in the alignment tool. |

Choosing the sensor to configure:

Entering the values copied from the Scan page into the corresponding parameters in the tool:

Make sure to do this for each sensor.

| 7. | If you have not already done so, finish configuring the rest of the tool's parameters. |

Note that the artificial offsets you use to create the combined heightmap for the alignment procedure are unrelated to the values you need to use in Origin X {n}; for more information on this setting, see Ring Layouts (Surface Align Ring Tool).